���܂}��ϵ�y(t��ng)

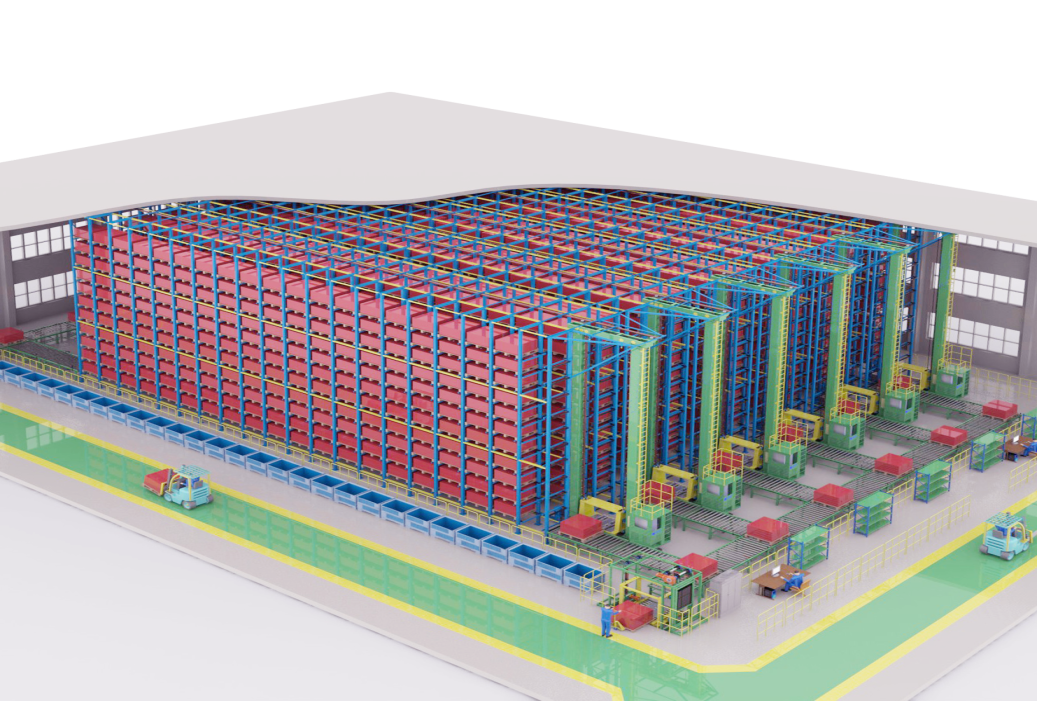

SMART STORAGE LIFTING SYSTEM

ϵ�y(t��ng)����

DESIGN PHILOSOPHY

ģ�K�������OӋ

Modular Family

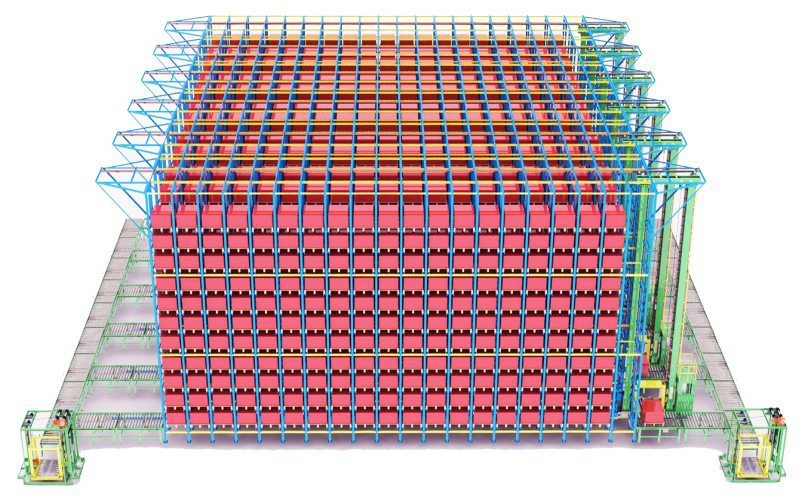

�p�����Ѷ�ϵ�y(t��ng)/

Duo-rail Storage Lifting System

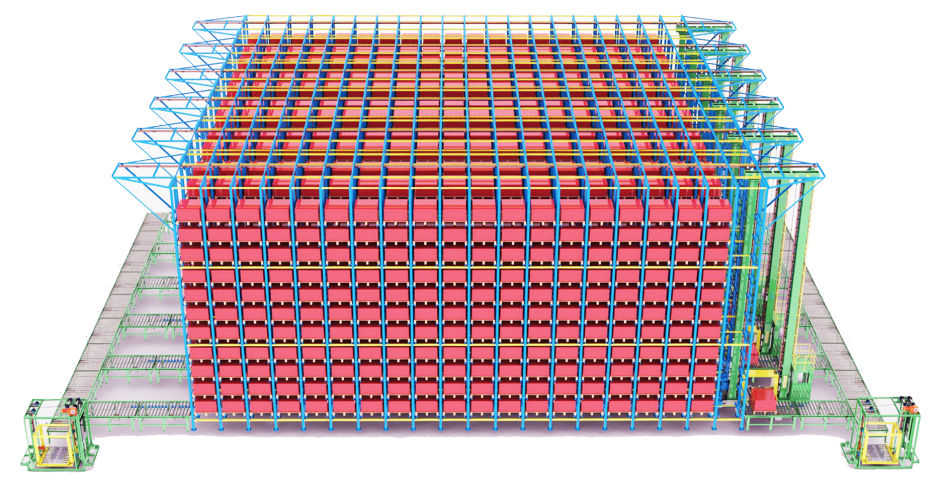

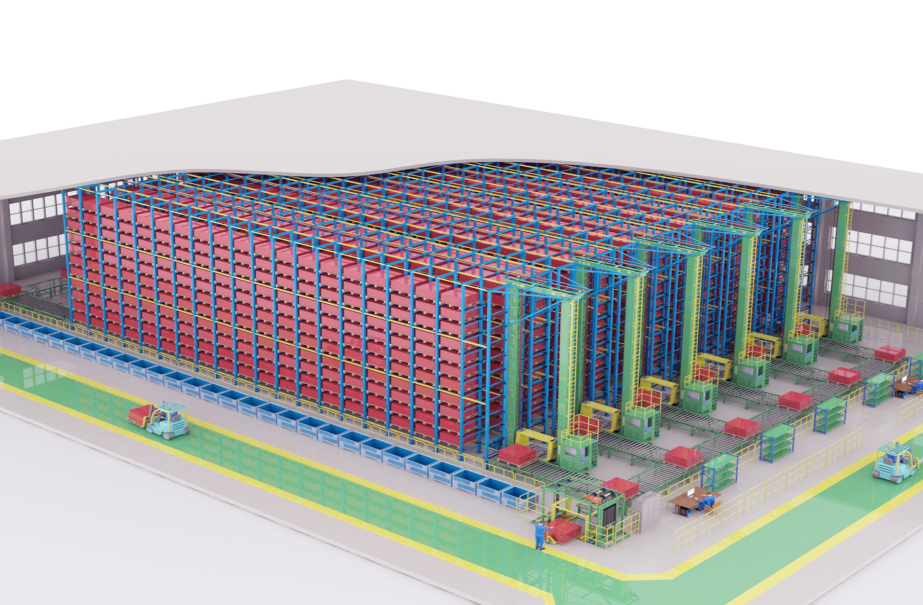

2��}�����\�wϵ

2 STORAGE LIFTING SYSTEM

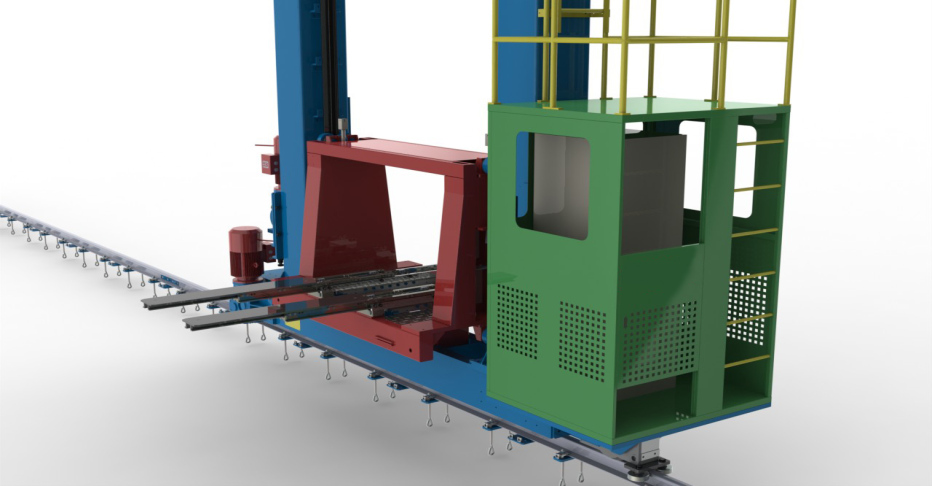

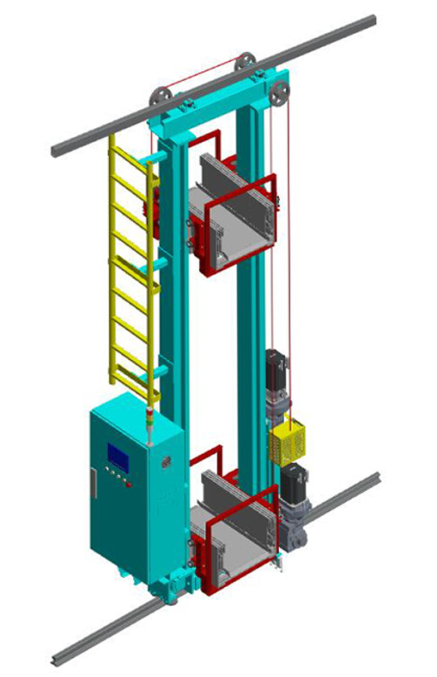

�������Ѷ�ϵ�y(t��ng)/

Mono-rail Storage Lifting System

ȫ��һ���߶ȿɿ��Ć������Ѷ�C��ּ�ڝM��͑�̎������׃��

���`����o���Ă}������ ����ˮƽ�����S�к���ȫ���{(di��o)��܉�����ֿɌ��F(xi��n)�߾��ȵČ��� ��������ʹ���(q��)�ӆ�Ԫ�͂�����������c���y(t��ng)�Ć������Ѷ�C����� ��Ҫ����ȵĿ���ϵ�y(t��ng)�� The new generation of highly reliable single column stacker is designed to meet customers' needs for handling more changes, More flexible and more compact storage requirements, maxium height 35meters, maxium load up to 1500 kilograms. The special horizontal guide bearing and fully adjustable track part can realize high precision guidance.Due to the limited use of drive units and sensors, compared with the traditional single column stacker, only minimum control system is required.

�҂��ṩ�����V���Ă}�����\ϵ�y(t��ng)�����m��С�͂}��������

ϵ�y(t��ng)���������w�}��������ϵ�y(t��ng)���F(xi��n)���_�l(f��)�˶�N��ͬ����̖��

���߶�35��, ����d����3000ǧ�ˡ�

����ϵ�y(t��ng)����ᘌ��}���ИI(y��)�Ķ�����r�������_�l(f��)����

����ּ������С�ľS�o�����F(xi��n)��Ч�ʵ��\����

We offer We offer a wide range of warehousing and handling systems,

From the system suitable for small-scale storage scene to large-scale three-

dimensional storage scene system.Many different models have been developed, maxium height 35meters, maxium load up to 3000 kilograms.

All the systems are first developed for the diversity of the warehousing industry,and it aims to achieve efficient operation with minimum maintenance.

�i���ṩ�߶��`��ļ��廯ģ�K�OӋ����ԭ�������ϵ�y(t��ng)�ṩ�O�ߵ�ͨ��������չ���������m����ǰ�����a(ch��n)�������֞���m(x��)�a(ch��n)�����`���{(di��o)���A���˾�ď�����

Pengya provides highly flexible family module design, which provides high universality and expansibility for the system from the original level. It can not only adapt to the current production scenario, but also reserve great flexibility for the flexible adjustment of subsequent production lines.

ģ�K�������OӋ�wϵ

MODULAR��FAMILY

�p�����Ѷ�ϵ�y(t��ng)

Duo-rail Storage Lifting System

��܉�ͷe��ʽݔ��

RAIL ACCUMULATING CONVOYOR SYSTEM

���ܿ���ϵ�y(t��ng)

Our conveyor system is only the "heart" of the built-in electrical control system.

The demand for system security and various system functions has grown rapidly in the past few years.

For more than 10 years, our internal control systems division has produced and built control and automation systems for conveyors.��Pengya's hardware and software functions are strongly integrated - high quality integration, no unnecessary interfaces.

We can provide:

�� Connection with customer ERP system

�� database coupling for order management

�� Filing process data into PLC control system

Our software and control solutions are designed based on a common control concept from field to manufacturing execution system (MES). The control and software products we use have modular designs that can be used to develop

and implement custom solutions.

Simulation and visualization

Through system simulation and visualization, we have outlined the material flow available to customers.The larger the conveyor system, the more complex it is, the more important it is to have an overview of all process steps and the status of the project to be addressed.The efficiency of the process ensures productivity and gives our customers a competitive advantage.

INTELLIGENT CONTROL SYSTEM

�����(q��)�����ИI(y��)����

SCENARIOS��DRIVEN

�҂���ݔ�͙Cϵ�y(t��ng)�H�ǃ�(n��i)��늚����ϵ�y(t��ng)�ġ����K����

ϵ�y(t��ng)��ȫ���Nϵ�y(t��ng)���ܵ��������^ȥ������Ѹ�����L��

����������҂�������ݔ�͙C��Q�����Ŀ���ϵ�y(t��ng)׃��Խ��Խ���s��

10��������҂��ă�(n��i)������ϵ�y(t��ng)���T��ݔ�͙C���a(ch��n)�ͽ����˿��ƺ��Ԅӻ�ϵ�y(t��ng)��

�i����Ӳ����ܛ��������ؽY����һ��-�����|(zh��)���ߣ��]�в���Ҫ�Ľӿ���

�҂������ṩ��

�c�͑�ERPϵ�y(t��ng)���B��

����ӆ�ι����Ĕ�(sh��)��(j��)�����

���^�̔�(sh��)��(j��)�w�n��PLC����ϵ�y(t��ng)

�҂���ܛ���Ϳ��ƽ�Q�����Ǹ���(j��)�ĬF(xi��n)���������(zh��)��ϵ�y(t��ng)��MES����ͨ�ÿ��Ƹ����OӋ����

�҂�ʹ�õĿ��ƺ�ܛ���a(ch��n)Ʒ����ģ�K���OӋ���������_�l(f��)�͌�ʩ���ƽ�Q������

ģ�M�Ϳ�ҕ��

ͨ�^ϵ�y(t��ng)ģ�M�Ϳ�ҕ�����҂������˿ɹ��͑�ʹ�õ���������ݔ�͙Cϵ�y(t��ng)Խ�� �����^�̲��E�ĸ��[�Լ�Ҫ̎�����Ŀ�Ġ�B(t��i)��Խ��Ҫ ���̵�Ч�ʿɴ_�����a(ch��n)��

���܂}��ϵ�y(t��ng)

SMART STORAGE LIFTING SYSTEM

50

+

���Ϳ͑�

180

+

�Ŀ��(j��ng)�

100

+

�a(ch��n)Ʒ�N�

30

+

�ИI(y��)���I��

�i�����ܿƼ����Ϻ�������˾�Գ����ԁ� �磺��(li��n)�W(w��ng)��ҕ����I(y��)�YԴ����ܛ��������\���S�Ԅӻ�ݔ��ϵ�y(t��ng)����Ӳ���\ӡˢ�·�剺��ϵ�y(t��ng)�� ��ʽ�����b�䡢�C���˰��\ϵ�y(t��ng)�����I(y��)Ϳ�bϵ�y(t��ng)���h(hu��n)����Դ�b�����߷��Ӳ��ϡ�

�κ����a(ch��n)������׃�ø������������ܱ������ȫ����Ч���M�����a(ch��n)�����ܻ��Ĺ��������F(xi��n)���I(y��)���ܻ���Ը��

�҂��������ǣ���(chu��ng)��rֵ����ͬ���L

�i�����ܞ锵(sh��)��Ӌ��֪��������I(y��)�ṩ�������������P�Ľ�Q������������I(y��)�����Ϣ��